Attolight’s technology is based on cathodoluminescence spectroscopy technology. Cathodoluminescence (CL) is a well known phenomenon that refers to the light emitted by any material under electron irradiation. The best known cathodoluminescence application is former television sets based on cathode ray tubes. CL becomes a very powerful defect inspection method when implemented in a modern electron microscope (EM) that is capable of fast, non-destructive defect inspection on a full wafer scale. Although cathodoluminescence has been known for a long time, technical implementations have been limited to manual laboratory use.

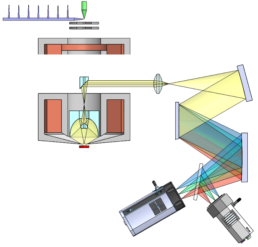

1. Attolight’s Fully Integrated Cathodoluminescence System Approach

Attolight is the only provider of fully integrated cathodoluminescence systems: Attolight designs, builds, and optimizes both electron and light optics to obtain high-efficiency CL collection while keeping the products simple to operate. Attolight’s cathodoluminescence systems are designed for both R&D and industrial environments with outstanding performance that is achieved thanks to proprietary & patented optical designs.

Typical competing solutions consist of a light collection add-on that is mounted on a standard Scanning Electron Microscope (SEM). This approach leads to sub-optimal performance in terms of reproducibility and light collection efficiency. Also, these systems need a dedicated operator who, in most cases, needs a solid scientific background in spectroscopy in order to use the system correctly. Finally, if the CL detection system is not performing up to specification, this could result from a problem in the SEM, the cathodoluminescence detection system, or in the detector alignment with the SEM. It can be difficult to know (a) whether alignment alone is the issue, and (b) if there is a system problem, which manufacturer to call in for a repair.

2. Quantitative Cathodoluminescence

Attolight’s light collection optics is designed so that the light collection efficiency is constant over a field of view (FOV) of 300 µm. This enables the user to quantitatively compare measured spectral shape, intensity, and wavelength position in different areas of the field of view. Competing solutions use a different light collection system in the form of a parabolic or elliptical mirror. Those systems feature by design a field of view of a couple of micrometers in the center axes of the optics.

3. Hyperspectral Cathodoluminescence

Hyperspectral or spectral imaging designates an advanced CL mode that registers the full emission spectrum at every excitation point. This mode needs a highly efficient light collection system together with high speed electronics and sensitive cameras.

Attolight’s products define hyperspectral cathodoluminescence by the capacity of generating images with 1600 channels – or colors – per pixel. Our technology provides millisecond hyperspectral cathodoluminescence maps with an acquisition time of one millisecond per pixel thanks to a high collection efficiency (NA=0.72), guaranteed zero photon-loss on apertures over a field of view of 300 µm, optimized control of the entire microscope – from the scanning coils to the camera –, and a very robust software solution capable of handling the huge data acquisition rate without stuttering.

4. Ultrafast Point Detection

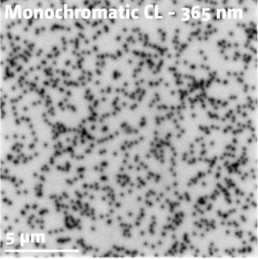

Ultrafast point detection (UPD) designates a cathodoluminescence detection mode in which an intensity at a given wavelength is recorded at every excitation point. This mode is radically different from hyperspectral mode (link) where full spectrum is registered at every excitation point.

UPD mode is mostly used to detect defects that show up at a given wavelength or are non-radiative like the dislocations shown on the picture here.

UPD is about 100 times faster than the hyperspectral mode which makes it very useful for a number of industrial applications where speed is key (about 1 minute for a hyperspectral map to below 1 s for a UPD map).

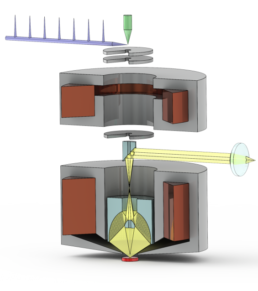

5. Pico-second Time-resolved Cathodoluminescence

Attolight’s tool can be field-upgraded to measure pico-second luminescence decay times. Change from continuous to time-resolved mode can be done on the fly with software control. This mode allows the measurement of minority carrier lifetimes and excited carrier diffusion distances. Conventional time-resolved cathodoluminescence systems use a beam blanker to “chop” the electron beam into short pulses. This approach however leads to a loss in spatial resolution and time-resolution can not reach the picosecond regime. This is why Attolight uses a revolutionary technique to obtain short pulses: make use of the photoelectric effect by focalising a short laser pulse on the electron emitter to cause photoelectron emission. By carefully synchronising the ultrafast detector to the excitation laser, time-resolutions below 10ps can be achieved. Attolight is the only company commercialising time-resolved cathodoluminescence systems based on this approach and has a world-wide unique experience in implementing and using such systems.

6. Short Time to Results

Sample alignment can be done within seconds by any user, no prior spectroscopy experience is needed. The alignment is done with the emission signal the user wants to measure yielding a perfect signal alignment. The readout of the light detection components is fully optimized to reach maximum measurement speeds. A hyperspectral map containing 40,000 pixels can be measured in just over 40s. This means that a hypercube of data is created that contains intensity information on 1,600 colours per pixel, a complete optical characterization of the sample within seconds.

7. Proprietary Electron Gun Design to Yield Highest Current Densities

The proprietary electron optics of the Attolight cathodoluminescence tool are custom designed in such a way as to yield highest current densities for electron spot sizes below 10 nm. The following specifications can be reached:

30 nA for a spot size below 10 nm

250 nA for a spot size below 25 nm.

This allows the Attolight system to produce more cathodoluminescence signal for a given acceleration voltage than competing SEM-CL configurations or to measure challenging materials such as Silicon that emit very low levels of light.

8. Lowest Sample Stage Drift Low Temperature Stage

Attolight’s low temperature solution can easily be added later as an upgrade without the need to change the sample stage, the upgrade can be carried out within hours. The Attolight cryostage solution shows extremely low drift, and, more importantly, no vibration measurable by the SEM. This is achieved by mechanically de-coupling vibrations by using a copper braid and a flow-free solution.

9. Intuitive Touch-screen Interface

Attolight’s tools are fully remote controlled by an intuitive user interface that is fully integrated on an iPad. This makes the user training very simple and the tool easy to use. All measurement data are registered on a server on the machine. Data can be read on any platform.

10. Data Analysis and Reporting Solution

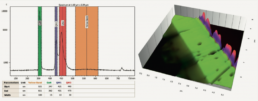

The Attolight CL microscope generates images containing up to 1,600 colors that are called hyperspectral maps. AttoMap is Attolight’s powerful solution for visualizing hyperspectral maps as 2D RGB maps or 3D maps and generating visual data analysis reports. AttoMap optimizes the workflow and creates interactive, traceable reports. In addition, AttoMap allows the user to visualize 2D RGB maps and has a powerful feature to create 3D maps. This feature is extremely helpful since it allows CL light intensity to be displayed in the third dimension giving the user a very simple way of representing complex data.

The figure shows an example of a 3D map. Colour bands are associated with relevant spectroscopic features. The 3D image makes it possible to immediately recognize emission intensity variations between features.

11. Electron Beam Induced Current (EBIC) Detection

The EBIC system (used to obtain high resolution electrical data on a sample) can be installed on initial installation or later as an upgrade. The EBIC module is fully compatible with the low temperature stage which can be important for certain types of samples. EBIC can be carried out in parallel with cathodoluminescence, even at low temperature, so both signals can be detected at the same time in the exact same working conditions.